5 Reasons Why Best Progressive High Speed Stamping Die Can Transform Your Manufacturing Efficiency

In the rapidly evolving landscape of manufacturing, the adoption of advanced technologies has become paramount for maintaining competitive advantage. The Progressive High Speed Stamping Die stands out as a game-changer in this realm, significantly enhancing production efficiency and precision. According to a recent industry report by MarketsandMarkets, the global stamping die market is projected to reach USD 25 billion by 2025, reflecting a surge in demand driven by the automotive and electronics sectors. This growth highlights the necessity for manufacturers to leverage high-speed stamping solutions to meet the increasing production demands while maintaining quality. With its ability to facilitate quicker cycle times and reduced operational costs, adopting the Progressive High Speed Stamping Die can propel manufacturers into a new era of productivity, making it an indispensable asset in the modern manufacturing toolkit.

Understanding Progressive High Speed Stamping Dies and Their Importance in Manufacturing Efficiency

Progressive high-speed stamping dies are becoming increasingly important in enhancing manufacturing efficiency, particularly in the automotive and metal stamping sectors. By allowing multiple operations to be executed in a single pass, these advanced dies streamline the production process, reducing cycle times and increasing output. The use of progressive dies enables manufacturers to create complex sheet metal parts efficiently, leading to significant cost savings and improved precision.

As the automotive fine blanking market is projected to grow from USD 6.5 billion in 2024 to USD 9.8 billion by 2033, the demand for technologically advanced stamping solutions is on the rise. Companies that invest in progressive stamping technology can capitalize on this growing trend, positioning themselves as leaders in a competitive market. Through the integration of innovative tooling solutions, manufacturers can enhance their production capabilities and meet the evolving needs of the industry. The strategic implementation of these high-speed dies plays a crucial role in not only optimizing current manufacturing processes but also ensuring long-term sustainability and growth.

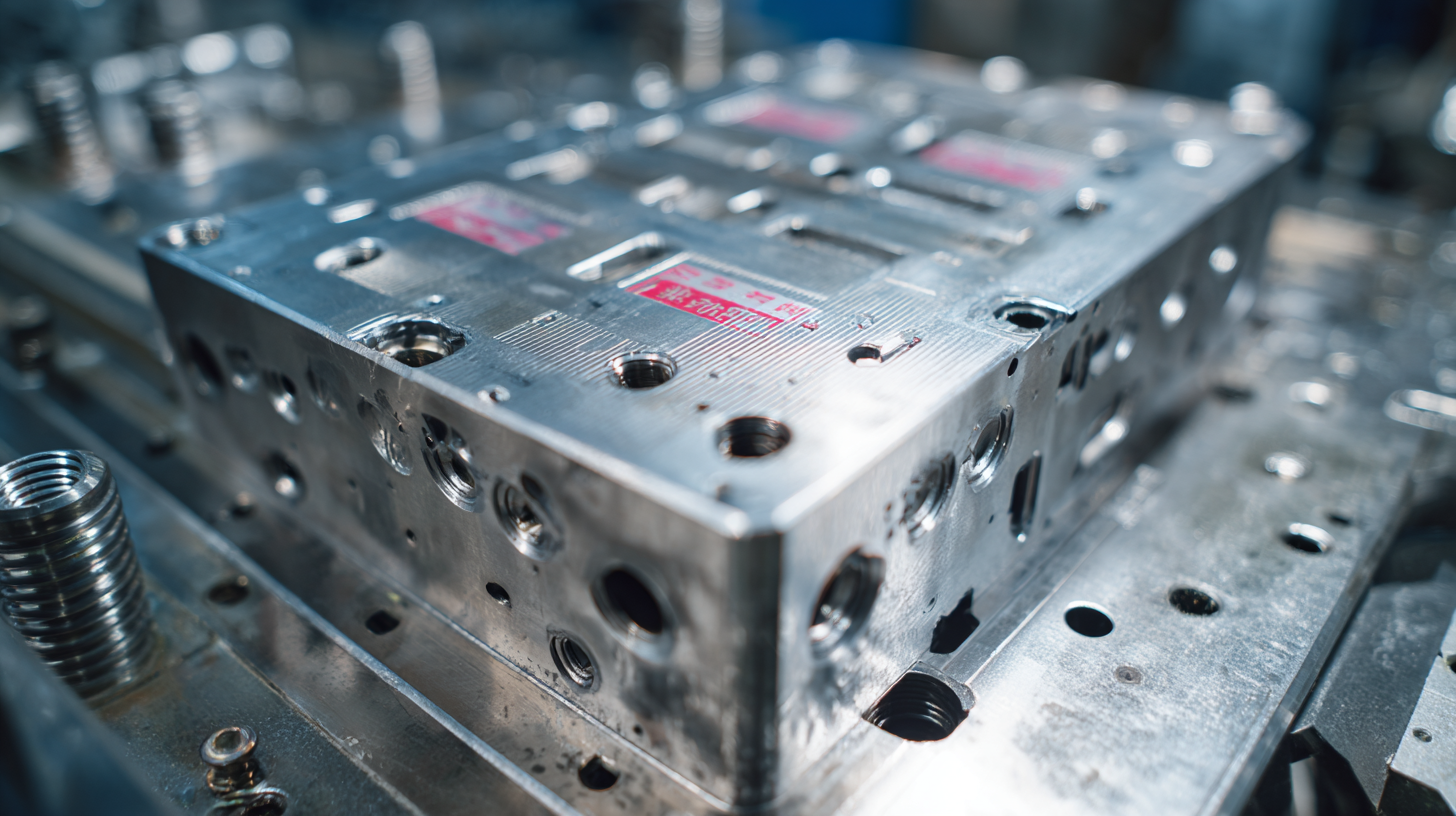

Key Features of Top-Quality Progressive High Speed Stamping Dies

In the manufacturing landscape, the selection of high-speed stamping dies is pivotal for enhancing production efficiency. Top-quality progressive high-speed stamping dies excel in several key areas. First, they are designed for precision, allowing manufacturers to achieve tighter tolerances, which is essential for industries like automotive where part quality is critical. According to recent market insights, the automotive fine blanking market is projected to grow from USD 6.5 billion in 2024 to USD 9.8 billion by 2033, highlighting the increasing demand for high-quality stamped components.

Another significant feature is their ability to streamline the manufacturing process. Advanced metal stamping technologies are transforming production lines by reducing cycle times and ensuring consistent output. A report anticipates that the metal stampings market will also see notable growth, driven by innovations that make processes more efficient across various sectors. Moreover, the emphasis on precision and productivity in press tool manufacturing cannot be overstated; high-speed stamping dies are fundamental in achieving these objectives, fulfilling the burgeoning market requirements for faster and more efficient operations.

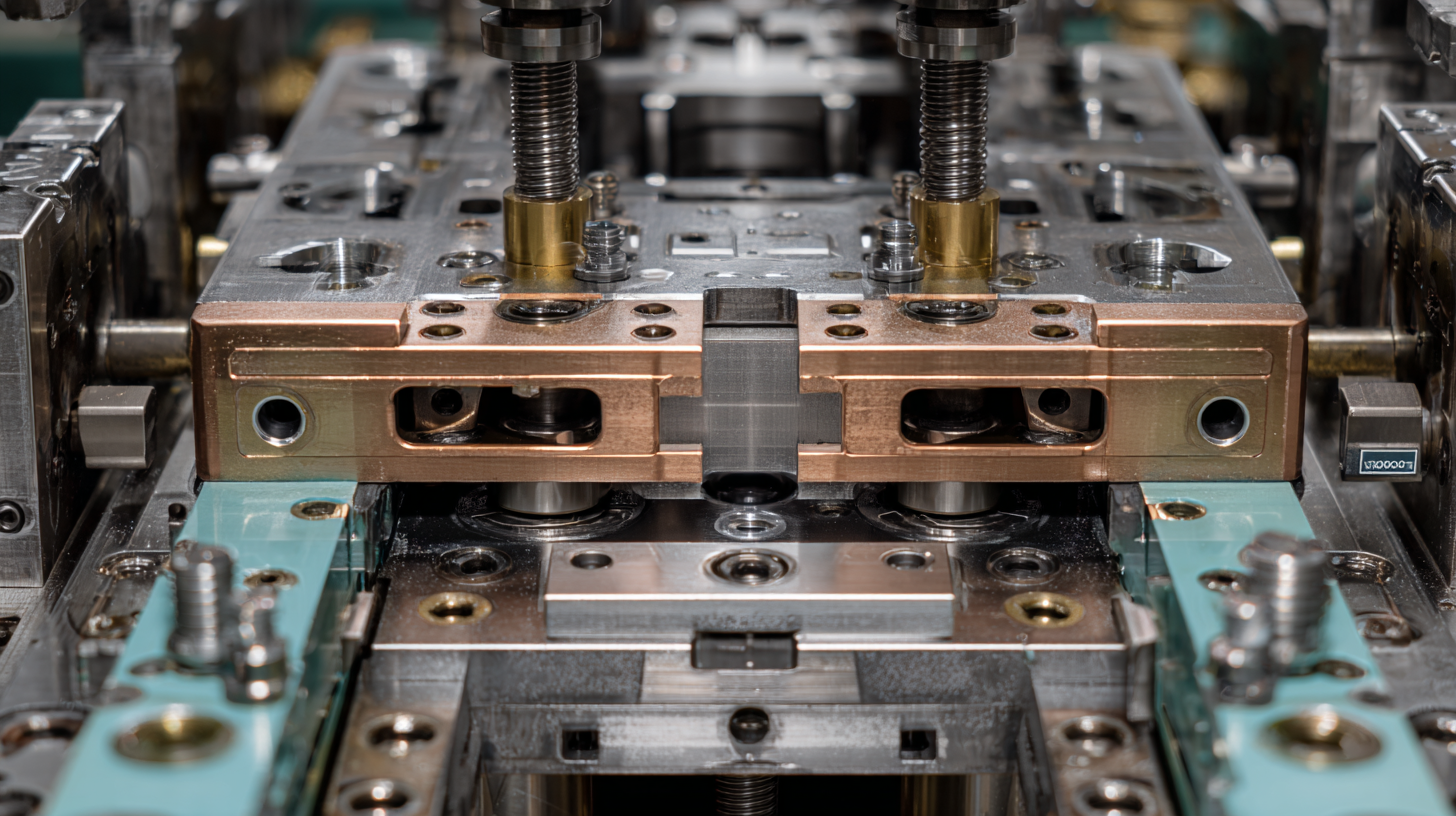

How Progressive High Speed Stamping Dies Enhance Production Speed and Precision

Progressive high-speed stamping dies are revolutionizing the manufacturing landscape by enhancing both production speed and precision. These advanced tools allow manufacturers to achieve a production rate as high as 1000 parts per minute, significantly reducing cycle times compared to traditional stamping methods. According to a recent industry report by Research and Markets, businesses that implement high-speed stamping can experience productivity increases of up to 30%, allowing them to meet stringent market demands rapidly.

To maximize the efficiency of progressive high-speed stamping dies, manufacturers should regularly inspect and maintain their equipment. Ensuring that dies are correctly aligned and lubricated can prevent costly downtime and extend tool life. Additionally, consider implementing automated systems to monitor production processes, as data-driven insights can help optimize operations and reduce waste.

Another key advantage of progressive high-speed stamping is its ability to produce complex parts with tight tolerances consistently. As reported by the American Metalforming Association, this level of precision can decrease the need for secondary operations, streamlining workflows and ultimately saving on labor costs. By integrating high-speed stamping dies into their processes, manufacturers can not only enhance their output but also elevate the quality of their products significantly.

Cost Savings and Waste Reduction with Advanced Stamping Die Technologies

In today’s competitive manufacturing landscape, cost savings and waste reduction are critical factors driving companies to adopt advanced stamping die technologies. The implementation of high-speed progressive stamping dies not only enhances production efficiency but also minimizes material waste. By allowing manufacturers to produce complex parts in a single automated process, these dies significantly reduce the need for secondary operations, which can often lead to additional costs and waste.

Moreover, the precision engineering of modern stamping dies ensures that materials are utilized to their fullest potential. Advanced technologies such as computer-aided design (CAD) and simulation software enable manufacturers to optimize die design before production begins, identifying any potential inefficiencies that could result in scrap. This proactive approach not only cuts down on material costs but also improves overall sustainability practices by reducing the volume of waste sent to landfills, aligning production methods with environmentally-friendly standards.

Adopting these innovative stamping die technologies is a smart move for manufacturers looking to enhance their operational effectiveness while keeping costs in check.

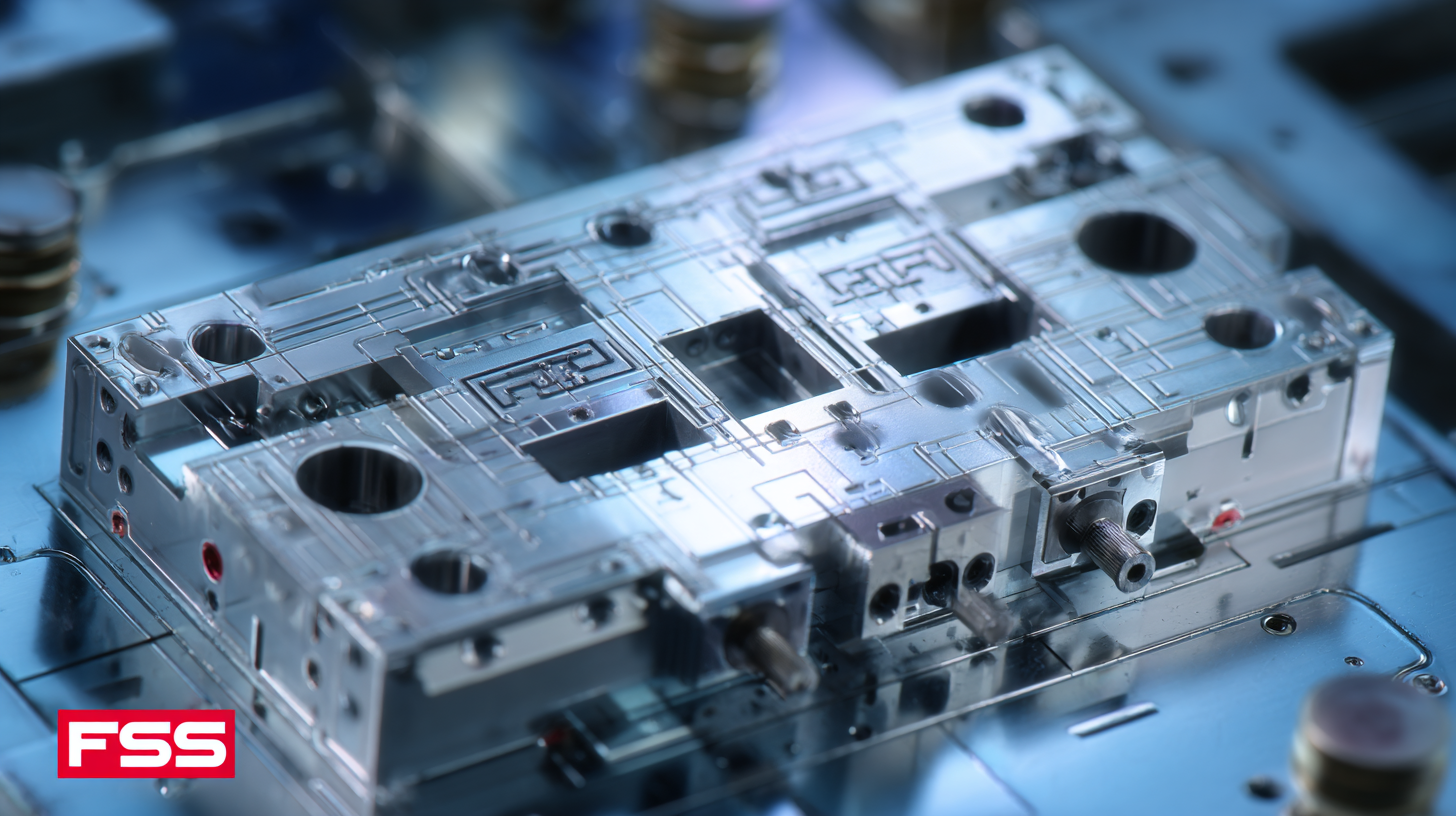

The Role of Customization in Maximizing the Benefits of Progressive Stamping Dies

Customization plays a pivotal role in enhancing the efficiency of progressive high-speed stamping dies. According to a report by Smithers Pira, the global demand for customized stamping solutions is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025. This growing trend is largely driven by manufacturers seeking to improve their production processes while reducing waste and operational costs. Customization allows companies to tailor dies to their specific requirements, ensuring optimal material flow and minimizing downtime during production.

Moreover, a study by the American Society for Quality indicates that implementing customized stamping dies can lead to a reduction in production time by up to 30%. This is particularly significant in industries such as automotive and electronics, where precision and speed are vital for maintaining competitive advantage. By aligning die design with the unique characteristics of the materials used and the desired output, manufacturers can achieve greater efficiency and higher quality standards. Ultimately, the integration of customized progressive stamping dies not only enhances manufacturing efficiency but also contributes to longer tool life and lower maintenance costs, further solidifying its importance in modern production environments.